- danish

- english

- afrikaans

- albanian

- amharic

- arabic

- armenian

- assamese

- aymara

- azerbaijani

- bambara

- basque

- belarusian

- bengali

- bhojpuri

- bosnian

- bulgarian

- burmese

- catalan

- cebuano

- corsican

- creole

- croatian

- czech

- deutsch

- dhivehi

- dogrid

- dutch

- estonian

- ewe

- filipino

- finnish

- french

- frisian

- galician

- georgian

- greek

- guarani

- gujarati

- haitian_creole

- hausa

- hawaiian

- hebrew

- hindi

- hungarian

- icelandic

- igbo

- indonesian

- irish

- italian

- japanese

- kannada

- khmer

- kinyarwanda

- korean

- kurdish

- kurdish_sorani

- kyrgyz

- lao

- latin

- latvian

- lithuanian

- luganda

- luxembourgish

- macedonian

- maithili

- malay

- malayalam

- maltese

- maori

- marathi

- nepali

- norwegian

- nyanja

- oromo

- pashto

- persian

- polish

- portuguese

- punjabi

- quechua

- romanian

- russian

- samoan

- sanskrit

- scottish_gaelic

- shona

- sindhi

- singapore

- slovak

- slovene

- somali

- spanish

- swahili

- swedish

- tajik

- tamil

- tatar

- telugu

- thai

- turkish

- turkmen

- twi

- ukrainian

- urdu

- vietnamese

- welsh

- yiddish

- yoruba

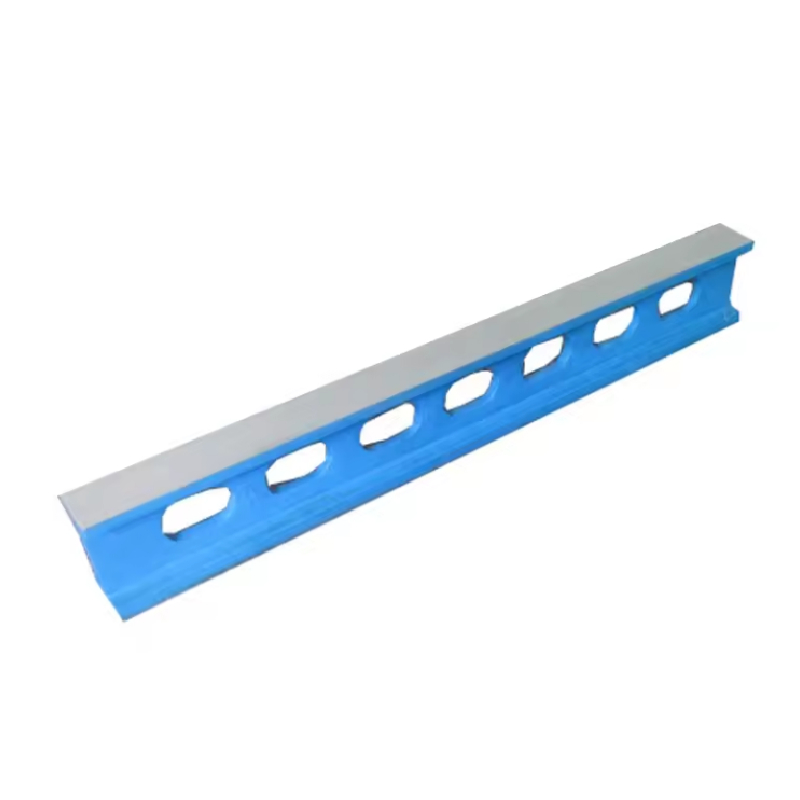

Faama tilennenw .

Product paramètre .

Yɔrɔ min bɛ bɔyɔrɔ la:Hebei, Sinuwa

Garanti:1 san

Dɛmɛn ka kɛɲɛ ni mɔgɔw sago ye:OEM, ODM, OBM

Marka tɔgɔ:Storan

Modèle numéro:2010

Matériel:Cast Nɛgɛ .

Tiɲɛni:

Baarakɛcogo cogoya:Kuma kɛcogo .

Item weight:customized .

capacity:customized .

Material:HT200-300

Specification (Sɛbɛnniw) sɛbɛn ɲɛ 10nan na walima a kɛcogo ladilancogo lajɛ .

Surface treatment (Furakɛcogo): Bolo-scraped walima fini-milling .

Foundry processus:Sand casting .

Ja: Ja min bɛ kɛ ni ja ye .

Surface coating:Baarakɛyɔrɔ min datugulen don ni tulu ye min bɛ kɛ ni pickling ye .

Baarakɛ funteni:(20±5)℃

Precision Grade:1-3.

A bɛ sɔrɔ ka kɛɲɛ ni mɔgɔw sago ye.A bɛ sɔrɔ

Packaging:Plywood Box .

Waati min bɛ kɛ ka baara kɛ .

|

Hakɛ (Pièces .) |

1 – 1 |

> 1 |

|

Ɲɛtaa waati (Tilew .) |

30 |

Ka kumaɲɔgɔnya kɛ . |

Suguya

* fara a bɛ kɛ cogo min na .

* A dilannen don ni nɛgɛ ye min ka bon kosɛbɛ.

* casting stress – lafiyali ka bɔ kɔnɔna degunw na.

* A bɛ dilan ka kɛɲɛ ni fɛn caman ye minnu bɛ kɛ ka caya: Kalanso 0, 1 ani 2.

* Nɔgɔw foroko ye plywood kɛsu ye, pake finmanw bɛ sɔrɔ ni ɲinini kɛra ni musaka wɛrɛ ye.

Fɛn minnu bɛ kɛ ka fɛnw ɲɛfɔ .

Fɛn min bɛ sɔrɔ a la: HT200-300 .

Ɲɛfɔli: A’ ye sɛbɛn ɲɛ 10nan lajɛ walima a kɛcogo ɲɛ .

Surface furakɛli: Bolo-sɔgɔlen walima finidoncogo .

Foundry Process: Sand casting .

Ja: Primer Peinture .

Surface Coating: Baarakɛyɔrɔ min datugulen don ni tulu ye min bɛ kɛ ni fɛn ye ani yɔrɔ min tɛ baara kɛ ni penisilini ye .

Baarakɛ funteni: (20±5 .)℃

Precision Grade :1-3 .

Conception Custom: A bɛ sɔrɔ

A bɛ kɛ ka fɛnw labɛn: Plywood Box .

Product paramètre .

|

Ayi. |

Bonya x Janya -MM .) |

Baara kɛyɔrɔ tilennen walima a flakɛ . |

Paralalisimu fila ni ɲɔgɔn cɛ baarakɛyɔrɔ fila ni ɲɔgɔn cɛ . |

||||

|

Degree de précision(μm) |

|||||||

|

1 |

2 |

3 |

1 |

2 |

3 |

||

|

1 |

500 × 45 |

6 |

12 |

|

9 |

18 |

|

|

2 |

750 × 50 |

8 |

15 |

|

12 |

25 |

|

|

3 |

1000 × 55 |

10 |

20 |

|

15 |

30 |

|

|

4 |

1200 × 60 |

12 |

24 |

|

18 |

36 |

|

|

5 |

1500 × 60 |

15 |

30 |

|

20 |

40 |

|

|

6 |

2000 × 80 |

20 |

40 |

80 |

27 |

54 |

|

|

7 |

2500 × 80 |

25 |

50 |

100 |

33 |

65 |

130 |

|

8 |

3000 × 100 |

|

60 |

120 |

|

78 |

156 |

nɛgɛ min bɛ kɛ ni nɛgɛ ye min bɛ kɛ ni nɛgɛ ye: a bɛ se ka muɲu & a bɛ se ka kɛ ko a bɛ se ka kɛ .

Ka mara tilennenw sugandi ka ɲɛsin iziniw ka ɲɔgɔnfaamu ma wa? Material Choice bɛ baara kɛcogo ɲɛfɔ. Storaen bɛ nɛgɛ ni nɛgɛ nɛgɛ tilennenw suma ɲɔgɔn na walasa k’a jira mun na an ka nɛgɛdaga tilennenw bɛ se ka kɛ sababu ye ka u muɲu ani ka u kɛ ka ɲɛ.

1. Fanga & Yɛrɛyɛrɛli kɛlɛli .

Nɛgɛ min bɛ kɛ ka a kɛ (HT200-HT300 .):

Ni 180–240HB gɛlɛya ani 300MPa tensile fanga ye, an ka nɛgɛ tigɛlenw ka fɛnɲɛnamafagalan ni bololanɛgɛw bɛ 3x don ka ɲɛ ka tɛmɛ nɛgɛ nɔgɔlen kan. A ka microstructure bɛ yɛrɛyɛrɛw nɔgɔya ni 40% ye, o nafa ka bon CNC masinw labɛncogo la walima ka baarakɛminɛnw sigicogo digi yɔrɔ min na masinw yɛrɛyɛrɛli bɛ filiw lase yɔrɔ min na.

Nɛgɛ:

A ka nɔgɔn (130–180HB) ani a ka teli ka sɔgɔsɔgɔ (ra ≥3.2μm), nɛgɛ tilennenw ka sariyatigɛlaw bɛ bɔnɛ teliya la teliya la sigidaw la minnu bɛ sɔgɔ, nɛgɛ min bɛ kɛ ni nɛgɛ ye, o tɛ se ka kɛ.

2. A sabatili kuntaalajan sabatili .

thermal consistance .:

Nɛgɛ min bɛ kɛ ka a ka funteni dɔgɔya (11,6×10⁻⁶/°C) o bɛ kalasi 0 tilennen mara (≤0,001mm/m 1000mm), a bɛ sabati 10°C–40°C kɔnɔ. Nɛgɛ bɛ 25% caya ka tɛmɛ, o bɛ farati lase ±5μm filiw ma minnu bɛ funteni jateminɛ baaraw la i n’a fɔ aerospace component alignment.

Surface durability .:

Stress-relieved ani ni a bɛ se ka kɛ ni bolo ye, nɛgɛ nɛgɛma tilennen bɛ RA ≤1.6μm gɛlɛya mara ka tɛmɛ 10.000 cycles kan. Nɛgɛ marabagaw bɛ 20% flakɛ bɔnɛ 5000 cycles kɔfɛ ka da micro-deformations kan.

3. corrosion protection & design pratique .

Finish min bɛ kɛ ka fɛnw tiɲɛ, o bɛ kɛ .:

5μm tulumafɛn min bɛ kɛ ka nɛgɛ mara, o bɛ nɛgɛ marabaga ka ɲɛnamaya janya ni 2x ye atelier nɛnɛmanw na, ka tɛmɛ nɛgɛdaga kan minnu bɛ nɔgɔ walima ka dingɛ sɔrɔ ka bɔ nɛnɛfɛnw na.

Ergonomi ka fɛnw .:

Basi 30–50mm janya ni lastikuw bɛ sɛgɛn dɔgɔya, ka sɔrɔ 500–3000mm hakɛ (labɛnni ka se 6000mm ma) Aw bɛ Steel ka wuliliko bali ka tɛmɛ 2000mm kan.

4. Waati min na i bɛ nɛgɛ suguya sugandi .

Ideal ka .:

sigida minnu ka gɛlɛn (sɔrɔw, masinw feereyɔrɔw) ni u bɛ se ka wuli ani funteni jiginni.

Baara minnu bɛ kɛ ni kɔrɔfɔ ye i n’a fɔ CMM jateminɛcogo walima sɛgɛsɛgɛliba min bɛ kɛ ka ɲɛsin fɛnw filili ma, n’o ye ko Steel ka dantigɛliw bɛ se ka baara kura musaka bɔ.

Hali ni nɛgɛ tilennenw bɛ bɛn yeelen baarakɛcogo ma, Storaen ka nɛgɛ nɛgɛma nɛgɛ tilennen ani dakun tilennen ni bololanɛgɛ bɛ 3x di ɲɛnamaya janya, yɛrɛyɛrɛli kunbɛncogo ɲuman, ani funteni sabatili. U bɛ dɛmɛ sɔrɔ san 1 garanti ni ladamuni fɛɛrɛw fɛ, u bɛ dɔ bɔ fɛntigiya musaka bɛɛ lajɛlen na iziniw labɛnni na. Aw ye an ka fɛn caman sɛgɛsɛgɛ bi ani ka danfara tigitigi sɔrɔ nɛgɛba la min bɛ wele ko premium cast.

Faama tilennenw bɛ dɛmɛ don cogo min na bolo-sɔrɔ-yɔrɔw la .

Bolo-scraping bearing surfaces bɛ micron-level precision de wajibiya, wa sariya tilennenw nafa ka bon kosɛbɛ walasa ka tiɲɛni ɲɛminɛ. Storaen ka ruler straight edge solutions bɛ nin bololabaara in bonya, ka gɛlɛya ni muɲuli di walasa ka yɔrɔ gɛlɛnw sɛmɛntiya ka kɛ ɲɔgɔndanba ye. An ka baarakɛminɛnw bɛ taabolo kɔrɔta cogo min na .:

1. Foundation de précision: straight edge alignment .

A nɛgɛ tilennen dakun sariya ye fɛnba ye walasa ka flakɛli sɛgɛsɛgɛli kɛ .:

Surface Inspection (Sɔrɔyɔrɔ sɛgɛsɛgɛli): Ni aw ye storaen inox straight edge ruler (RA ≤1.6μm) bila, o bɛ yɔrɔ caman jira yeelenbɔlanw fɛ, ka a jira ko 2 tilennenw (≤0.02mm/m for 1000mm). O bɛ scraping tigitigi ɲɛminɛ walasa ka 25–30 contact points/25x25mm dilan, ka doni tilali ɲuman kɛ birikiw kɔnɔ.

guided scraping: An ka sariya sira tilennen da gɛlɛn bɛ scraper angles basigilenw sabati, ka tigɛcogo bɛnbaliw bali. turbine minnu bɛ kɛ ni wazi ye walima CNC spindles, o bɛ dɔ bɔ ɲɔgɔnkanu na ni 30% ye ani ka a yɔrɔw ɲɛnamaya kɛ siɲɛ fila ye.

2. Fɛn minnu bɛ kɛ ka ɲɛsin mago suguya caman ma .

Storaen bɛ faama tilennenw di .:

Nɛgɛ tilennenw (HT200-HT300): Ni 180–240HB gɛlɛya ye, o bɛ se ka resist deflection kɛ kilo 50 tansiyɔn na, ka ±5μm tilennen mara 300mm kan—a ka ɲi ka baara gɛlɛnw kɛ i n’a fɔ dizili motɛri birikiw, yɔrɔ min na jiginni tɛna nɔ bila ɲɔgɔndɛmɛ na.

inox straight edge rulers (304 grade): A bɛ se ka sɔgɔ ni 20μm nikɛri-kɔrɔma plati ye, u bɛ tilennen kalasi 3 (≤0.05mm/m) di kɔgɔji walima furakɛli sigidaw ma, ka u tanga nɛnɛmada ma ani ka a jira ko u bɛ se ka kɛ pɔnpew walima furakɛli minɛnw ye.

3. baarakɛcogo ɲuman & tiɲɛni .

An ka metal straight edge ruler bɛ baarakɛcogo ɲuman sɔrɔ .:

Ergonomi dilancogo: Basi min janya ye milimɛtɛrɛ 30 ye ani lastikuw minɛcogo, o bɛ sɛgɛn dɔgɔya sɔgɔsɔgɔninjɛ waati janw na, ka sɔrɔ balansi girinyalen bɛ sabatili sabati yɔrɔ jɔlenw/yɔrɔjanw kan—a ka gɛlɛn ka biriki belebelebaw labɛn fiɲɛbɔlanw walima fiɲɛbɔlanw kɔnɔ.

Calibration Assurance: Faamu bɛɛ bɛ GB/T 6091-2004 sariyaw labato 3D laser sɛgɛsɛgɛli fɛ, ka kunnafoni dilen di ISO 1101 sariya labatoli ma.

4. Storaen ka nafalanw .

Custom Solutions: Dilancogo minnu bɛ kɛ ka kɛɲɛ ni 2000mm ye, olu bɛ se ka kɛ ni 120° ye ka ɲɛsin biriki kurulenw ma (4–6 dɔgɔkun ɲɛtaa waati) bɛ bɛn aerospace walima geometries kɛrɛnkɛrɛnnenw ma.

A muɲuni : nɛgɛ modɛliw bɛ tulu 5μm sɔrɔ walasa ka nɔgɔ kunbɛn; Inox bɛ kɛ ni passivation ye, ka baarakɛminɛnw ɲɛnamaya janya ni 2x ye sigida gɛlɛnw na.

Garanti: San 1 lakanani ka bɔ dimension drift la, o bɛ dannaya sabati ka se ≤0.01mm/m parallelism sɔrɔli ma, ka baara seginni dɔgɔya masinw na minnu nafa ka bon.

Bolo-scraping bɛ seko ni dɔnko fara ɲɔgɔn kan, ani Storaen ka faama tilennenw bɛ o fila bɛɛ lase. K’a ta nɛgɛtigɛlan tilennenw na minnu bɛ se ka sɔgɔ ni nɛgɛ ye, ka se nɛgɛ modɛliw ma minnu bɛ kɛ ni nɛgɛ ye, an ka baarakɛminɛnw bɛ tiɲɛni ni muɲuli di, min ka kan ka kɛ ni biriki kɔrɔlenw ye. Aw bɛ aw ka bololabaara kɔrɔta ni baarakɛminɛnw ye minnu dilannen don bi fɛn dilanni kama—yɔrɔ min na, fɛn bɛɛ bɛ jate ka kɛɲɛ ni masinw ka dannaya ni baarakɛcogo ye.

Produit detail ja .

Related PRODUCTS