- danish

- english

- afrikaans

- albanian

- amharic

- arabic

- armenian

- assamese

- aymara

- azerbaijani

- bambara

- basque

- belarusian

- bengali

- bhojpuri

- bosnian

- bulgarian

- burmese

- catalan

- cebuano

- corsican

- creole

- croatian

- czech

- deutsch

- dhivehi

- dogrid

- dutch

- estonian

- ewe

- filipino

- finnish

- french

- frisian

- galician

- georgian

- greek

- guarani

- gujarati

- haitian_creole

- hausa

- hawaiian

- hebrew

- hindi

- hungarian

- icelandic

- igbo

- indonesian

- irish

- italian

- japanese

- kannada

- khmer

- kinyarwanda

- korean

- kurdish

- kurdish_sorani

- kyrgyz

- lao

- latin

- latvian

- lithuanian

- luganda

- luxembourgish

- macedonian

- maithili

- malay

- malayalam

- maltese

- maori

- marathi

- nepali

- norwegian

- nyanja

- oromo

- pashto

- persian

- polish

- portuguese

- punjabi

- quechua

- romanian

- russian

- samoan

- sanskrit

- scottish_gaelic

- shona

- sindhi

- singapore

- slovak

- slovene

- somali

- spanish

- swahili

- swedish

- tajik

- tamil

- tatar

- telugu

- thai

- turkish

- turkmen

- twi

- ukrainian

- urdu

- vietnamese

- welsh

- yiddish

- yoruba

3D welding table .

Product paramètre .

Yɔrɔ min bɛ bɔyɔrɔ la:Hebei

Garanti:1 san

Dɛmɛn ka kɛɲɛ ni mɔgɔw sago ye: OEM, ODM

Marka tɔgɔ (Storan

Modèle numéro:2005

Product Name:3D Flexible weld platform matériel .

Material: Nɛgɛ/Steel .

Aplikasi (Industrie

Pore hakɛ muɲuni:

Surface treatment t:Surface Nitriding .

Flatness:0,02mm/1000mm

Roughness:Ra1.6-Ra3.2.

Processus: CNC Machining .

suguya (Baarakɛcogo caman .

Seereyaw (ISO9001:2008

Package details (Plywood Box 3D welding table avec accessoires OEM HT300 Oxide black 3D Table flexible flexible

Unités feereli (Single Item .

Foroko kelen bonya:100x100x20 cm

Kisɛ bɛɛ lajɛlen: 5000 kg .

Waati min bɛ kɛ ka baara kɛ .

|

Hakɛ (Pièces .) |

1 – 100 |

> 100 |

|

Ɲɛtaa waati (Tilew .) |

5 |

Ka kumaɲɔgɔnya kɛ . |

3D welding table .

3D welding platform ye welding platform ɲɛtaa ye, o ye plateforme ye .

ani fan naani bɛ tilatila ni dingɛ 28 ye , minnu bɛ kɛ ka ɲɔgɔn sɔrɔ ni .

3D flexible fixture, ka se ka baara kɛ teliya la ani ka baarakɛminɛn siri .

O ka kan ka welda. 3D welding platform nafa ye baarakɛcogo ɲuman ye, .

Precision (hakɛ) caman, ani musaka dɔgɔman. 3D welding baarakɛminɛnw kulu dɔ bɛ se ka basigi .

Aw bɛ kiliyanw ka welding yɔrɔw bɛɛ wasa.

Product paramètre .

|

3D welding tabali ɲɛfɔli sɛbɛn . |

|||||

|

D28 Series . |

D16 Series . |

||||

|

Numɛriw . |

A ɲɛfɔli . |

girinya |

Numɛriw . |

A ɲɛfɔli . |

girinya |

|

JM-D28-1010 |

1000*1000*200 |

380KG |

JM-D16-1005 |

1000*500*100 |

70KG |

|

JM-D28-1212 |

1200*1200*200 |

430KG |

JM-D16-1010 |

1000*1000*100 |

120KG |

|

JM-D28-1015 |

1000*1500*200 |

450KG |

JM-D16-1208 |

1200*800*100 |

120KG |

|

JM-D28-1020 |

1000*2000*200 |

600KG |

JM-D16-1212 |

1200*1200*100 |

170KG |

|

JM-D28-1224 |

1200*2400*200 |

850KG |

JM-D16-1015 |

1000*1500*100 |

180KG |

|

JM-D28-1520 |

1500*2000*200 |

880KG |

JM-D16-1515 |

1500*1500*100 |

270KG |

|

JM-D28-1530 |

1500*3000*200 |

1300KG |

JM-D16-1020 |

1000*2000*100 |

250KG |

|

JM-D28-2030 |

2000*3000*200 |

1800KG |

JM-D16-1224 |

1200*2400*100 |

350KG |

|

JM-D28-2040 |

2000*4000*200 |

2700KG |

|

|

|

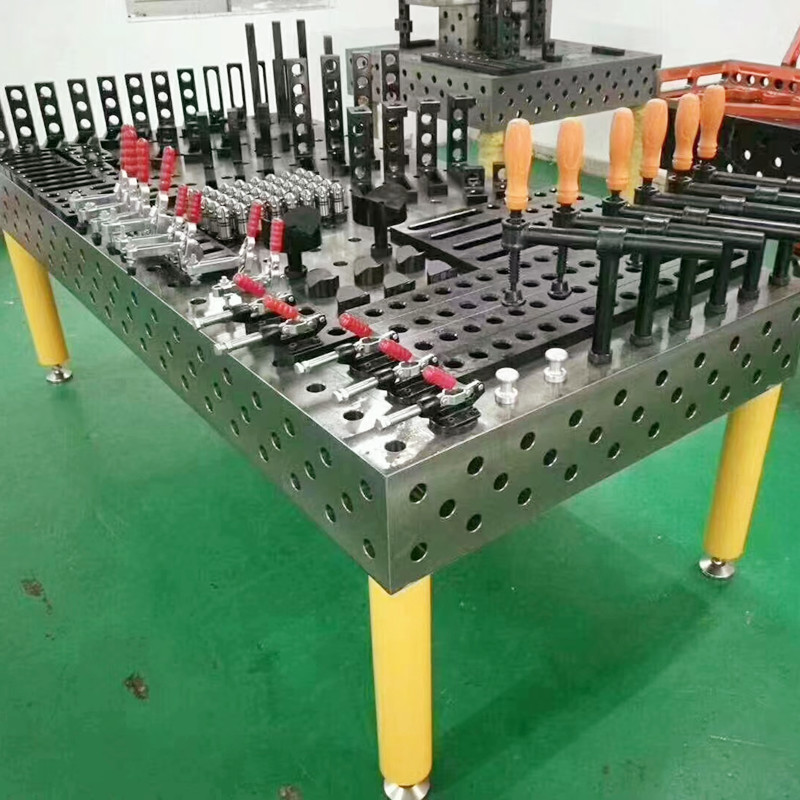

Fɛn minnu bɛ sɔrɔ fɛn dilannenw na .

Components bɛ se ka kɛ ni i ye nin sugandi ninnu kɔfɛ .:

1, Baarakɛminɛnw dɛmɛni: U cogoya kubɛri kɛsu, L cogoya kubɛri, angle support, ani angle gauge

2, Yɔrɔ minnu bɛ sɔrɔ yɔrɔ la walasa ka yɔrɔ sɔrɔ .:

3, baarakɛminɛnw walasa ka u siri ani ka u labɛn .

4, Yɔrɔ minnu bɛ kɛ ka baara kɛ ni u ye .

5, baarakɛminɛnw dɛmɛni .

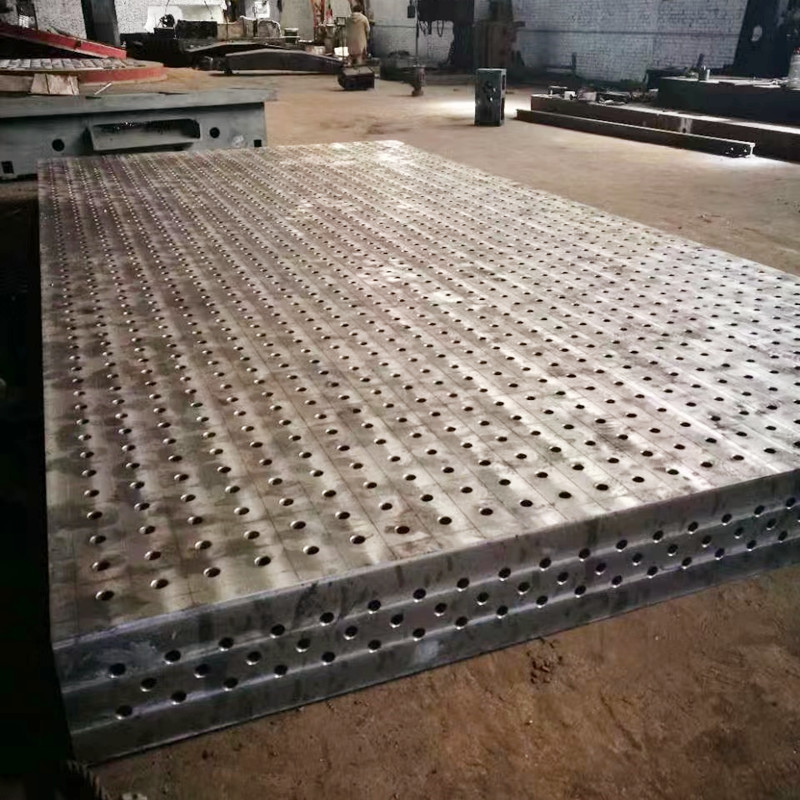

3D welding Tablo 1.2×2.4 1×2 1.5×3 2x4m Have in stock cast nɛgɛ tabali ani fixture tabali .

- - Dimensions:1000X1000mm-2000X4000mm

- - Baarakɛyɔrɔ duuru Yɔrɔ min bɛ se ka sigi sen kan, o bɛ se ka sigi sen kan. fana bɛ se ka janya a ka baarakɛyɔrɔ duuru dɔ fɛ.

- - A kɔnɔfɛnw tilalen don: nɛgɛw ka sofa tabali (Q345) ani welding tabali (HT300).

- - A dingɛ cɛmancɛ tilalen don: D28 seriyali ani D16 seriyali.

- - Diagonal grid: D28 ye 100*100mm ye; D16 ye 50*50mm ye.

Suguya

Dɛmɛn .: Senw, nɛgɛdaga, ani jibolisiraw, ka kɛɲɛ ni wajibi ye.

3D welding platform ye diɲɛ bɛɛ ka fɛn ye min dilannen don kɛrɛnkɛrɛnnenya la fɛnw dilanni na minnu bɛ kɛ ka fɛnw sɔgɔ; A bɛ kɛ ka welding convenience, flexibilité, ani caman danfara bɔ ni laadala welding fɛɛrɛw ye.

Saba-yɔrɔ-yɔrɔ-ko-sistema faralen ɲɔgɔn kan welding process flexible.

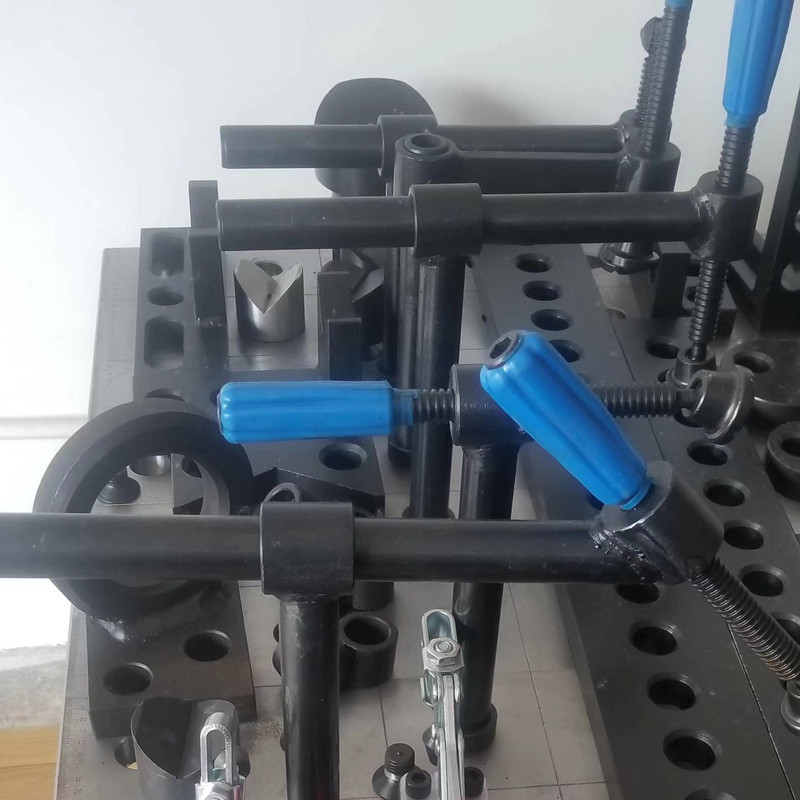

Dimensions saba .: bɛ sira saba jira. A ka c’a la, fiɲɛw bɛ janya ani u bɛ tɛmɛn ni sira jɔlenw tɛ. Plateforme in sira fila bɛ yen, wa a dakun naani bɛ se ka kɛ ka sigi sen kan, ka se ka fɛn saba fara ɲɔgɔn kan.

Dingɛw ka sigida .: Nin fiɲɛbɔlan in kɔnɔko jɔnjɔn ye ko k’a ta plateforme la ka taa a bila fɛnw na, dingɛw bɛ yen minnu tɛ sariya ye, laadala jiriw walima T-slots tɛ minnu na. Ni aw ye a fara ɲɔgɔn kan ni da teliya la, a lajɛli bɛ se ka kɛ teliya la ani ka nɔgɔya, wa a jɔyɔrɔ bɛ se ka sɔrɔ.

Farankan: Ikomi fɛn bɛɛ faralen don ɲɔgɔn kan, u bɛ se ka fara ɲɔgɔn kan ka u ladilan ka kɛɲɛ ni fura in magow ye.

Flexibilité .: Ni baara minnu fɔra sanfɛ, minɛnw kulu bɛɛ bɛ se ka Changer ka kɛɲɛ ni fɛn dilannen caman yeli ye. Fɛn caman bɛ se ka kɛ fɛn caman walima fɛn tan caman magow ye, ka fɛnw ɲinini ni u dilanni ni u kɛcogo teliya kosɛbɛ, ka baarakɛlaw caman mara, ka nafolo sɔrɔ, ka nafolo sɔrɔ, ani ka nafolo sɔrɔ (fɛn minnu bɛ kɛ ni teriw ye sigida la ani minnu tɛ gazi ye).

Welding .: Nin fɛn in ye fɛn ye min bɛ kɛ diɲɛ bɛɛ kɔnɔ min dilannen don kɛrɛnkɛrɛnnenya la fɛn dilannenw dilanni kama; A bɛ kɛ ka welding convenience, flexibilité, ani caman danfara bɔ ni laadala welding fɛɛrɛw ye.

Anti-rust primer wajibiyalen jɔnjɔnw 3D welding plateforme kan, olu ye : nɔrɔ ɲuman ka ɲɛsin casting sanfɛla ma, anti rust baarakɛcogo ɲuman, nɔrɔ ɲuman ka kɛ penti sanfɛla la, ani jɔli ni mara nɔgɔya.

Top features ka kan ka ɲini 3D welding tabali kɔnɔ .

Ni aw bɛ 3D welding tabali sugandi, a nafa ka bon ka fɛn suguya caman jateminɛ minnu bɛ dɔ fara kosɛbɛ baarakɛcogo ni tiɲɛni kan aw ka welding porozew kɔnɔ. 3D welding tabali ɲumanba bɛ se ka danfara bɛɛ kɛ ka ɲɛtaa ɲumanw sɔrɔ. Nin ye sanfɛla ye min ka kan ka ɲini .:

1. So jɔli barikama : 3D welding tabali barikama ka kan ka dilan ni fɛnw ye minnu ka bon kosɛbɛ, minnu bɛ se ka doni girinmanw muɲu ani welding kɛcogo gɛlɛyaw. Aw bɛ tabali ɲini minnu dilannen don ni nɛgɛ ye min bɛ mɛn walima nɛgɛ min bɛ kɛ ka u kɛ nɛgɛ ye, o bɛ a to a ka mɛn ani a ka sabati.

2. Modularity: Se ka i ka setup kɛ ka kɛɲɛ ni mɔgɔw sago ye ani k’a ladilan, o nafa ka bon kosɛbɛ. Modular 3D welding table bɛ sira di farankanw ni fɛn wɛrɛw faralen ɲɔgɔn kan, o b’a to i bɛ se k’i ka baarakɛyɔrɔ labɛn walasa a ka bɛn porozɛ kɛrɛnkɛrɛnnenw ma, a kɛra fɛn fitininw ye minnu dilannen don ni fɛn fitininw ye walima lajɛbabaw.

3. Masini tigitigi : Walasa ka tiɲɛniba sɔrɔ, 3D welding tabali kɔnɔ yɔrɔw ni yɔrɔw ka kan ka kɛ ni masin ye tigitigi. Tabali ɲini minnu bɛ grid pattern di ni dingɛw ni sɔgɔlanw ye minnu bɛ yɔrɔ janyalen na, minnu bɛ baarakɛminɛnw sirili ni u jɔcogo nɔgɔya.

4. Clamping options versatile : Clamping fura ɲumanw nafa ka bon kosɛbɛ walasa ka sabatili sabati welding kɛtuma na. 3D welding tabali ɲuman ka kan ka jiginni yɔrɔ suguya caman ni sirilanw di, o bɛ kɛ sababu ye ka fɛnw cogoya sɛgɛsɛgɛ ani ka u minɛ cogo la min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye.

5. Ka bɛn ni fɛnw ye minnu bɛ se ka kɛ: Aw ye aw jija ka 3D welding tabali min sugandi, o bɛ bɛn ni fixture systems suguya caman ye. O bɛnkan in bɛna dɔ fara i ka seko kan ka setups customs da joona ani ka ɲɛ, ka waati kisi i ma ani ka dɔ fara baarakɛcogo kan.

6. Yɔrɔ furakɛli : yɔrɔ min bɛ nɔgɔ ni sɛgɛn kɛlɛ, o nafa ka bon kosɛbɛ welding sigida la. Aw bɛ tabali ɲini ni anti-spatter coatings walima finiw ye minnu bɛ dɛmɛ ka baarakɛyɔrɔ saniyalen mara ani ka tabali ka ɲɛnamaya janya.

Nafa minnu bɛ sɔrɔ 3D welding table la walasa ka baara kɛ ka ɲɛ .

Nɛgɛ dilanni diɲɛ kɔnɔ, ka tiɲɛni ni tiɲɛni sɔrɔ, o de ye fɛnba ye porozɛw ɲɛtaa kama. Baarakɛminɛn minnu bɛ se ka kɛ weldalaw ye, olu dɔ ye 3D welding tabali tigitigi ye. O minɛn nafama in tɛ dɔrɔn ka dɔ fara baarakɛcogo kan, nka a bɛ baara dafalen fana kɛcogo ɲɛ kosɛbɛ.

3D welding tabali tigitigi dilannen don ni sigida barikama ye min bɛ se ka kɛ sababu ye ka setupw kɛ minnu bɛ se ka ladilan ka kɛɲɛ ni poroze kelen-kelen bɛɛ ka wajibi kɛrɛnkɛrɛnnenw ye. A ka c’a la, a sanfɛla bɛ kɛ ni fɛnw ye minnu ka ɲi kosɛbɛ, a bɛ se ka muɲu ani ka sabati welding baara waatiw la. O sabatili bɛ se ka nɛgɛ yɔrɔ minnu bɛ baara kɛ, olu tiɲɛni walima u tiɲɛni bali, o min nafa ka bon kosɛbɛ walasa ka sariyaw mara minnu ka ɲi kosɛbɛ.

Nafa belebele wɛrɛ min bɛ sɔrɔ 3D welding tabali tigitigi la, o ye jiginni ni fɛnw ye minnu bɛ se ka kɛ a la. O tabali caman bɛ na ni T-slots walima dingɛw ye minnu bɛ se ka weldalaw dɛmɛ ka yɔrɔw siri ka ɲɛ. O kɛcogo in nafa ka bon poroze caman na, yɔrɔ min na, labɛnni ɲuman marali nafa ka bon kosɛbɛ. O de kosɔn, farati bɛ ɲɔgɔn na ani filiw la, o bɛ dɔgɔya kosɛbɛ, o bɛ kɛ sababu ye ka welda saniyalenw ni tigitigiw sɔrɔ.

Ka fara o kan, baara kɛli ni 3D welding tabali ye min bɛ se ka baara kɛ, o bɛ se ka baarakɛcogo ɲɛ ani ka waati dɔ dɔgɔya min bɛ kɛ poroze kelen-kelen bɛɛ la. Ni baarakɛyɔrɔ dantigɛlen dɔ bɛ di, min bɛ labɛn ani min bɛ baara kɛ ka ɲɛ, weldalaw bɛ se ka u sinsin kosɛbɛ u ka baara dacogo n’u ka fɛɛrɛko siratigɛ la sanni ka sinsin sigicogo kan. O baara kɛcogo ɲuman in bɛ na ni sɔrɔ hakɛ caman ye ani laban na nafa ɲuman sɔrɔli jagokɛlaw fɛ.

Kuncɛli la, ka wari bila 3D welding tabali tigitigi la, o ye tulonkɛfɛn ye min bɛ se ka kɛ sababu ye ka baarakɛla ŋanaw ka weldala ɲini walasa k’u ka bololabaara yiriwa. A ka se ka sabatili, ladamuni, ani baarakɛcogo ɲuman di, a ye baarakɛminɛn nafamaba ye min bɛ welding baara ɲuman ni tigitigi dɛmɛ. I mana kɛ dɔnnikɛla ye min bɛ se kosɛbɛ walima n’i ye novice ye welding foro la, ni i bɛ baara kɛ ni 3D welding table précision ye, siga t’a la ko o bɛna i ka porozew kɔrɔta ka se hakɛ wɛrɛ ma.

3D welding tabali baarakɛcogo jɔnjɔnw ani izini baarakɛcogo .

Storaen ka 3D welding tables bɛ ɲɛfɔli kɛ ka ɲɛ ani ka baarakɛcogo ɲuman sɔrɔ iziniw ka welding dilanni na, ka kɛ fɛn caman ye minnu bɛ se ka baara kɛ ni modulariw ye minnu dilannen don walasa ka baarakɛminɛnw sigicogo, fɛnw labɛnni, ani fɛn caman welding baarakɛcogo nɔgɔya. Anw minnu ye welding fabrication tables ɲɛmɔgɔ ye, an bɛ fɛɛrɛw di minnu bɛ gɛlɛyabaw, cogoyaw labɛn minnu bɛ se ka ladilan, ani tiɲɛni minnu bɛ se ka segin-ka-bɔ—fɛn minnu nafa ka bon bi fɛn dilanni sigidaw la minnu bɛ welding zeru-defecte jaabiw ɲini.

Precision positionnement (Jɛkulu jɔyɔrɔ tigitigi) .

An ka 3D welding table design kɔnɔ, dingɛ duuru bɛ yen minnu bɛ kɛ ni fɛnw ye minnu dilannen don ni fɛnw ye (D28 walima D16 seriyali), o bɛ se ka kɛ sababu ye ka sirilanw, kɛrɛw, ani fɛnw sirilanw nɔrɔ ɲɔgɔn na cogo la min tɛ fɛn tiɲɛ ani kɛrɛfɛ panɛri naani bɛɛ. Nin grid system (100x100mm walima 50x50mm spacing) bɛ jɔyɔrɔ tiɲɛni sabati ±0.05mm kɔnɔ, ka jateminɛ kɛcogo bɔ a la ka yɔrɔ gɛlɛnw labɛn i n’a fɔ mobili chassis frames, aerospace brackets, walima heavy-duty machinery yɔrɔw. O kɔlɔlɔ ye? welding setup repeatable min bɛ dɔ bɔ kɔrɔbɔli ni fili la ni 60% ye, o nafa ka bon kosɛbɛ jamana sɔrɔli la yɔrɔ min na bɛnkan tɛ se ka kɛ ɲɔgɔn fɛ.

Module flexibilité pour différents fabrication needs .

An ka welding fab tables bɛ ɲɛtaa sɔrɔ ladamuni kan .:

Platforme multi-platform integration: standard sizes (1000x1000mm ka se 2000x4000mm) bɛ se ka siri ɲɔgɔn na ni pinɛ teliyalenw ye, ka baarakɛyɔrɔ janyalenw dilan porozew kama minnu ka bon kosɛbɛ—a ka ɲi kurunbokarilanw walima sɛnɛ minɛnw lajɛli la.

Baarakɛminɛnw tɛ fɛn minnu na, olu bɛ ɲɔgɔn sɔrɔ: A bɛ bɛn ni welding fɛn caman ye (U-blocks, T-slots, magnetic clamps), tabali bɛ sira di teliya la ka baara suguya wɛrɛw kɛ, tigɛcogo sigicogo waati ni 50% ye ni i ye a suma ni laadalata taabolow ye.

Loavy-duty load capacity: A bɛ dilan ni HT300 nɛgɛ ye walima Q345 nɛgɛ ni a jukɔrɔla ye ribbed ye, o tabali bɛ doni jɔlenw muɲu fo ka se kilo 2700 ma, o bɛ hali izini yɔrɔbaw dɛmɛ ni deflection tɛ—a ka kan ka kɛ schevator arm welding walima crane structure fabrication ye.

Industriw ka baarakɛminɛnw: Yɔrɔ min na tigitigi bɛ nafa sɔrɔ baarakɛcogo la .

Mobili dilanni .

Aw bɛ baara kɛ ni welding fabrication table ye walasa ka mobili farikolow lajɛ ɲɔgɔn fɛ, ka spot welds bɛ ɲɔgɔn sɔrɔ ±0.1mm kɔnɔ walasa ka OEM jogo sariyaw dafa. Anti-spatter coating option bɛ surface lakana ka bɔ welding debris la, ka baarakɛ waati janya fɛn dilanni siraw la minnu ka bon kosɛbɛ.

Aerospace & Lafasali .

A nafa ka bon kosɛbɛ ka aliminiyɔmu nɛgɛmafɛnw dilan minnu ka nɔgɔn (misali la, awiyɔn motɛriw, yɔrɔ min na tabali ka funteni sabatili (min ka bon ni funteni ye funteni jukɔrɔ) ani flatness (0,02mm/1000mm) bɛ dimensionnel deviation bali min bɛ se ka flight safety (boli lakanani) tiɲɛ.

Masina & Minɛnw .

Go-to solution for welding bulldozer frames walima industrial pompe casings, k’a sababu kɛ a jɔli barikama n’a dilancogo modulari ye min bɛ baarakɛminɛnw ladon minnu bɛ kɛ cogo la min tɛ fɛn ye, ka tɛmɛn fɛnw labɛnni fɛ minnu bɛ kɛ ka kɛɲɛ ni mɔgɔw sago ye.

Mun na Storaen 3D welding tabali bɛ sira ɲɛminɛ .

Baara kolomaw kɔ fɛ, an ka tabaliw bɛ sɔrɔ .:

Surface Finish Excellence: Dugukolo sanfɛla dɔ (RA1.6-RA3.2) bɛ a to a ka se ka fɛnw lamagacogo nɔgɔya ani ka ɲɔgɔn sɔrɔ tigitigi, ka sɔrɔ furakɛli nitiriyali min bɛ se ka kɛ ni option ye, o bɛ sɛgɛnbaliya fanga bonya abrasive welding environments kɔnɔ.

Duniya bɛɛ ka sariya labatoli: A seereyalen don ISO 9001 ani JB/T7974-99, an ka 3D welding tabali bɛ diɲɛ fɛn dilanni sariyaw ɲinini gɛlɛnw dafa, ka hakili sigi porozew kɔnɔ minnu bɛ dancɛ tigɛ.

Aw bɛ aw ka welding kɛcogo kɔrɔta ni Storaen ye .

Ni aw mago bɛ welding table compact la prototyping walima 3D welding table belebele kama mass production, Storaen’s solutions bɛ tiɲɛni, muɲuli, ani fɛn caman sɛgɛsɛgɛli di walasa ka to ɲɛfɛ bi fɛn dilanni na. Ni sigili waati dɔgɔyara, ka fixture compatibilité (finiko bɛnkan) caya, ani ka tiɲɛni segin-ka-bɔ, an ka tabali bɛ welding (welding) caman sɛmɛntiya ka bɔ bololabaara la, fili bɛ se ka kɛ cogo min na ka kɛ baarakɛcogo ye min bɛ kɛ ka ɲɛ, min bɛ kɛ ni otomatiki ye — min bɛ se ka i ka kulu fanga bonya, ka teliya, ka teliya, ani ka daŋaniya sɔrɔ min tɛ se ka suma ni ɲɔgɔn ye.

Accessoires systems ani custom solutions ka ɲɛsin 3D welding tables ma .

Storaen ka 3D welding tabali bɛ dafa ni accessoires systeme bɛɛ ye ani tailored custom solutions, minnu dabɔra ka fɛn caman, fɛnsɛbɛnni, ani ladamuni caman kɛ welding fabrication mago bɛɛ la. I mana kɛ fɛn jɔnjɔnw ye walasa ka se ka fɛn caman sɛmɛntiya walima ka fɛn caman sɛmɛntiya poroze kɛrɛnkɛrɛnnenw kama, an ka sarakaw bɛ i ka welding fabrication table caman sɛmɛntiya ka kɛ baarakɛyɔrɔ kɛrɛnkɛrɛnnenba ye — min bɛ kɛ ka bi fɛn dilanni ɲinini tigitigiw dafa.

Modular accessoire ecosystem ka ɲɛsin integration ma min tɛ se ka kɛ .

An ka plug-and-play accessories bɛ i ka welding fab table baarakɛcogo ɲɛ, ka se ka fɛn caman sɛmɛntiya teliya la ani ka baara kɛcogo ɲuman sɔrɔ .:

Dɛmɛ & Nivoya baarakɛminɛnw: Nɛgɛ senw ladilantaw ni anti-vibration pads bɛ se ka sigicogo sabatilen sɔrɔ butiki dugumalanw kan minnu tɛ kelen ye, ka sɔrɔ hydraulique lifting systems (100–500mm janya hakɛ) bɛ se ka kɛ sababu ye ka ergonomic positionnement kɛ sanfɛ walima welda gɛlɛnw na.

Fixturing & clamping solutions: A suguya caman, toggle clamps, ani U-blocks (min bɛ bɛn D28/D16 Hole Systems) baarakɛminɛnw ma minnu cogoya ni u bonya bɛɛ, ni teliya-bɔ-fɛɛrɛw bɛ fixture installation waati dɔgɔya ni 40% ye. Angled brackets (0–90° adjustable) ani precision squares bɛ dɛmɛ don axis multi-axis alignment la, min nafa ka bon kosɛbɛ jamalajɛ gɛlɛnw na i n’a fɔ robow walima aerospace trusses.

Lakanali & Lakanali farankanw: Anti-spatter coatings (a bɛ kɛ tabali yɔrɔw la) ani splash guards minnu bɛ se ka bɔ, olu bɛ nɔgɔw dalajɛli dɔgɔya, ka sɔrɔ matarafali minnu bɛ funteni kɛlɛ, olu bɛ grid system lakana ka bɔ welding arcs (sɔgɔlilanw) la waati jan kɔnɔ—o bɛ tabali baara ɲɛnamaya janya fɛnw dilanni na minnu fanga ka bon kosɛbɛ.

Custom Solutions: Engineed ka ɲɛsin i ka yeli ma .

Dimensions & configurations (Dimensions & Configurations) .

Ka tɛmɛn hakɛ dantigɛlenw kan (1000x1000mm fo 2000x4000mm), an bɛ 3D welding tabali dilan ka kɛɲɛ ni ladamu janya ye, a bonya, ani a janya ye—o la, a bɛ kɛ ni fɛnw ye minnu ka bon kosɛbɛ (ka se 5000x3000mm ma) walasa ka porozew kɛ minnu bɛ kɛ ka ɲɛsin iziniw ma. Siginiden minnu tɛ rectangulaire ye (circular, L-shaped) ani minnu bɛ don so kɔnɔ, olu bɛ masin kɛrɛnkɛrɛnnenw walima robow welding automatiques (otomatikiw) ladon, o bɛ a to i ka don i ka fɛn dilanni sira kan cogo nɔgɔman na.

Fɛn minnu bɛ kɛ ka ɲɛ .

Hole System Customization: Adjust Hole Spacing (misali la, 75x75mm for hybride grids) walima ka metric/imperial thread types (M12, 1⁄2”-13 UNC) ɲɛfɔ walasa ka bɛn fiɲɛw ma minnu bɛ yen, o bɛ kɛ sababu ye ka adaptɛri platiw mago bɔ.

Surface furakɛli: Aw bɛ dugukolo finiw sugandi (Ra1.6 for standard use) walima super-finished surfaces (RA0.8 for metrology-grade alignment), ni nitriding optional (HV900+) ye walasa ka gɛlɛya bonya ani ka abrasive sɛgɛnw kunbɛn baara gɛlɛnw na.

Yɛlɛma minnu bɛ kɛ iziniw kɔnɔ .

Mobili: T-slots intégrés pour convoyeur belt alignment, min ka ɲi ka ɲɛsin mobili teliyaba yɔrɔ welding cellules ma.

Aerospace : Inserts inox non magnétiques walasa ka NDT (sɛgɛsɛgɛli min tɛ tiɲɛni ye) minɛnw bali ka don a la, aluminiyɔmu sɔgɔli welding waati la.

Kɔgɔjida: Epoxy-coated undersides for corrosion resistance in Kɔgɔjida laminiw na, u faralen ɲɔgɔn kan ni nkɔni barajuru barikamaw ye kɔgɔjida la rig component fabrication kama.

rapid turnaround & diɲɛ bɛɛ ka dɛmɛ .

Stock Accessoires: Klansenw, senw, ani nivoya baarakɛminɛnw fanba bɛ ci sanga 24 kɔnɔ, o bɛ kɛ sababu ye ka baara bilali waati dɔɔnin dɔrɔn de kɛ ka ɲɛsin fɛn dilanni siraw ladilanni ma.

Laadalata waati: Tabali ladamulenw (minnu tɛ fɛn ye minnu tɛ fɛn ye) bɛ lase tile 15–20 kɔnɔ, ni dɛmɛ kɛrɛnkɛrɛnnen ye ɛntɛrinɛti kan walasa ka jaw ni fɛnw sugandili nɔgɔya (misali la, nɛgɛ intanw ka ɲɛsin dumuniw ma).

Certified Quality: 3D welding tables customs bɛɛ bɛ sɛgɛsɛgɛli gɛlɛnw kɛ (0.02mm/1000mm) ani doni tali tiɲɛni, o bɛ fara ISO 9001 ka jateminɛ kɛlenw kan minnu bɛ tali kɛ jogoɲini na minnu bɛ se ka tugu.

Aw ye aw ka welding fab table ka seko dafalen da .

Ni Storaen ka fɛnw ye minnu bɛ kɛ ka fɛnw labɛn ani u ka fɛɛrɛw, i ka welding fabrication table bɛ kɛ ka tɛmɛ baarakɛminɛn kan—o ye fɛnkurabɔli yɔrɔ ye min bɛ se ka sɛgɛsɛgɛ. I mago bɛ fɛnw na minnu tɛ sɔrɔ fɛnw na walasa ka nafa sɔrɔ teliya la walima 3D welding tabali min bɛ kɛ ka kɛɲɛ ni fɛn ye min bɛ se ka kɛ fɛn ye, an ka jɛkulu bɛ ɛntɛrinɛti dɔnniya ni fɛn dilanni teliya fara ɲɔgɔn kan walasa ka fɛɛrɛw di minnu bɛ bɛn i ka yeli ma. Aw bɛ aw ka welding baara kɔrɔta ni fɛn wɛrɛw ye minnu bɛ ladamu ani ka ladamu minnu bɛ fɛn caman sɛmɛntiya—bari a dilanni na, a tiɲɛni ye fɛn bɛɛ ye, wa hakɛ kelen tɛ bɛn bɛɛ ma abada.

Fɛn minnu bɛ sɔrɔ fɛn dilannenw na .

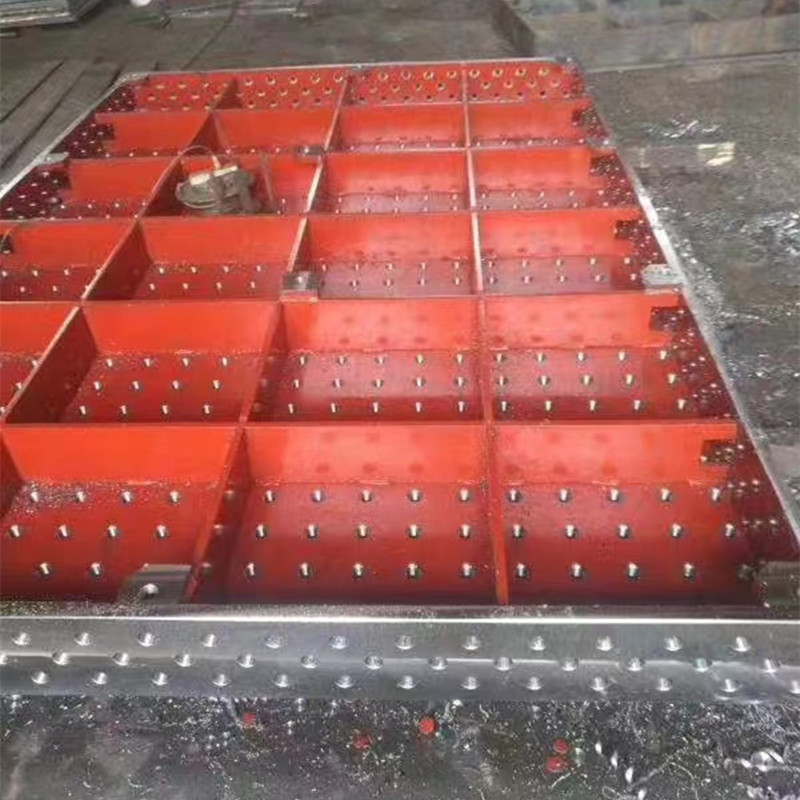

Anti-rust primer min bɛ kɛ ka caya, o ye penti ye min bɛ kɛ ni tulu ye. Paint de resin naturelle. Penti asphalt. Fositɛri penti, a ɲɔgɔnnaw U ka baara kɛcogo n’u ka baarakɛcogo bɛ danfara. A weldalen flati plati saniyalen don. Sɛgɛsɛgɛli tɛmɛnen kɔ. A ka c’a la, anti rust penti bɛ kɛ yɔrɔw la minnu tɛ dilan walima yɔrɔ bɛɛ. Ni a bɛ kɛ, a ka kan ka faamuya kosɛbɛ ko welding flat plates sugandili n’u dilanni na, a ka c’a la, bololabaarakɛcogo ka nɔgɔn. Sɔrɔko siratigɛ la, a bɛnnen don ani a bɛnnen don ka kɛ fɛn kelen ye min bɛ kɛ ka fɛnw dilan.

- T he baarakɛyɔrɔ min bɛ welding platform. Baarakɛyɔrɔ min bɛnnen don anti-rust penti suguya caman ma, o tɛ kelen ye. O la, ni a bɛ sugandi, mɔgɔ ka kan ka baarakɛyɔrɔ faamuya min bɛ sɔrɔ plati flat weldalen na.

- Primer ni topcoat man kan ka bɛn. welding flat plates, ka fara primer kan. Wa a ka kan ka penta a sanfɛ. Topcoat fanba bɛ kɛ masinw baara kɔfɛ, o la, a ka kan ka jateminɛ kɛ primer ni topcoat cɛ. A ka c’a la, primers ni topcoats minnu labɛnna ni penti fɛnw ye minnu ni ɲɔgɔn bɔlen don, olu bɛ bɛn ɲɔgɔn ma. Primers ani topcoats minnu labɛnna ni penti suguya wɛrɛw ye, olu bɛ se ka kɛ u tɛ bɛn u nɔrɔli barikama ma. U tɛ se ka jɛɲɔgɔnya ɲuman kɛ ni ɲɔgɔn ye. O la, a ka kan ka penisilini kɛcogo faamuya.

- Anti-Rust primer jɔcogo. Anti-rust primer kelen-kelen bɛɛ n’a ka jɔli ni a ka finidoncogo ɲuman don. Walasa k’a jira ko izini walima atelier bɛ ni o cogoyaw ye, weldalen flati bɛ dilan ka kɛɲɛ ni JB/T7974-99 sariya ye. Fɛn min bɛ kɛ, o bɛ kɛ ribbed plate ani box suguya ye. Baarakɛyɔrɔ ɲɛda bɛ ni cogoya kɛrɛnkɛrɛnnen ye, a dilannen don ni HT200 fɛn ye. Baarakɛ ɲɛda bɛ scraping ni grinding technology ta, wa V-cogo bɛ se ka kɛ masin ye baarakɛ ɲɛda la. T-cogo. U cogoya la, jirisunw ni dingɛw sɛrɛkiliw. dingɛ janw, a ɲɔgɔnnaw welding flat plate ye flat reference baarakɛminɛn ye min bɛ kɛ ka baarakɛminɛnw sɔgɔ, ani plate fla ka kan ka ladilan ka kɛɲɛ ni horizontal ye ka kɛɲɛ ni a sigili wajibiyalenw ye. O doni bɛ tila-tila cogo kelen na dɛmɛyɔrɔ kelen-kelen bɛɛ kan. Ni aw bɛ baara kɛ ni lamini funteni ye min ye 20 ± 5 °C ye, aw ka kan ka aw yɛrɛ tanga yɛrɛyɛrɛ ma.

Produit detail ja .

Related PRODUCTS